A proper maintenance and lubrication will help the machine in a perfect working condition.

Let’s see the below details together:

Preventive maintenance

Turn off engine and disengage all command levers. Engine must be cool.

Inspect the general condition of the unit. Check for loose screws, misalignment or binding of moving parts, cracked or broken parts, and any other condition that may affect its safe operation.

Remove all debris and other materials that may have accumulated to the track and unit. Clean after each use. Then use a premium quality lightweight machine oil to lubricate all moving parts.

Never use a “pressure washer” to clean your unit. Water can penetrate tight areas of the machine and its transmission case and

cause damage to spindles, gears, bearings,

or the engine. The use of pressure washers

will result in shortened life and reduce Serviceability.

Adjusting clutch

As clutch wears out, the same lever could have a wider opening, being so uneasy to use. This means that it is necessary to adjust the cable, setting clutch lever on its original position acting on the adjustment device and on counter-nut.

Adjusting steering

If you have difficulty steering the unit, you will need to adjust the steering levers with the special adjusters.Slacken off the locknut and unscrew the adjusters to eliminate the play in the cable, which can occur after initial use or normal wear. Be very careful not to unscrew the adjusters too much because this can create another problem: the loss of traction. Remember to tighten the locknut when you have finished.

Lubrication

The gearbox is pre-lubricated and sealed at the factory. Check oil level every 50 hours of working. Remove the plug and check, with machine horizontal, oil reaches the two notches. If necessary, add the oil.

Use portable tool lithium #0 grease such as Lubriplate 6300AA , Lubriplate GR-132, or Multifak, e.g. EP-O.

Oil must be replaced when hot by unscrewing filler cap and plug equipped with an oil dipstick. When oil is completely drained, replace filler cap and fill up with new oil.

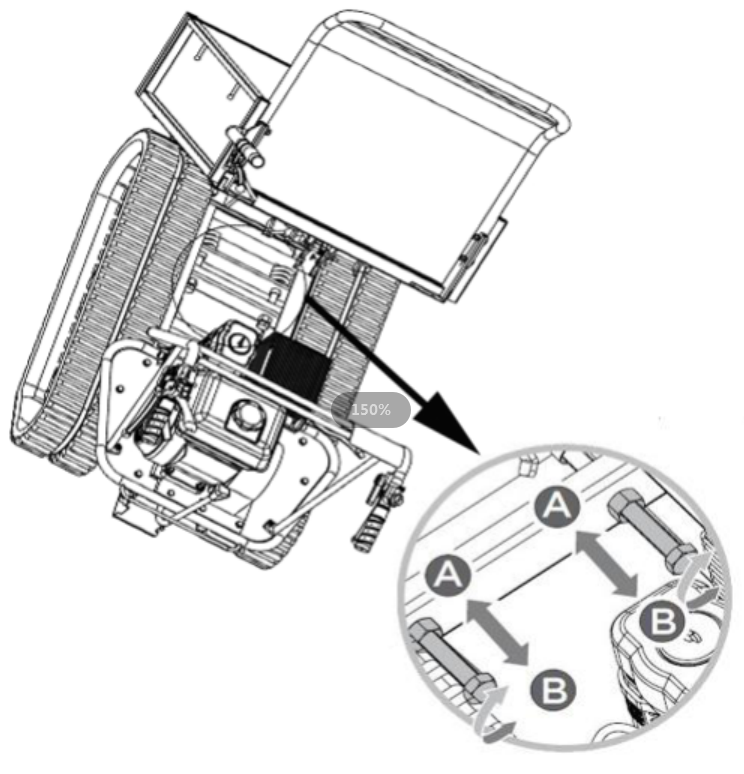

Tightening tracks

With use, tracks tend to loosen. When operating with loose tracks, they tend to slip over the driving wheel causing it to jump its housing or to work in precarious situation, thus damaging wear to the housing.

To check track tightness, proceed as follows.

1. Set the machine on a flat surface with compact ground, better on an asphalt or stone pavement.

2. Lift the machine and set it on blocks or supports rated for the weight of the machine so that the tracks are approximately 100mm off the ground.

3. Measure the track midline vs. the horizontal line. The reading must not be more than 10-15mm.

If the distance is greater, proceed as follows.

1. Use the tipping handle to tip the dump box and set it on blocks or supports rated for the weight of the box.

2. Loosen locknut A.

3. Tighten bolt B until the correct tightness is restored.

4. Secure bolt B by tightening locknut A thoroughly.

5. Return the dump box to its original position.